Electrophotographic printing, commonly known as laser printing, is one of the most widely used printing technologies in both commercial and industrial sectors. Improvements in imaging systems, toner quality, and digital workflows have greatly improved its efficiency, quality, and consistency. The demand for fast, high-resolution, and low-cost printing is increasing across industries. Innovations in EP technology are constantly taking place.

The article below provides information on the latest developments in electrophotographic printing and its diverse applications. According to the Concegic report, this market is expected to grow from $3,561.44 million in 2024 to $5,407.69 million by 2032.

Advancements in Electrophotographic Printing Technology

In electrophotographic printing, there has been a greater emphasis on increasing print resolution, reducing environmental impact, and increasing operational efficiency. Technological advancements have been made to make production processes more rapid and accurate, saving both time and cost. The major developments that have contributed to the growth of EP technology are as follows-

High-Resolution Imaging and Improved Laser Scanners

Modern electrophotographic printers use high-precision laser and LED exposure systems for sharp and clear imaging. Multi-beam laser diodes and digital micromirror devices achieve resolutions in excess of 2400 dpi, enabling clear and accurate display of fine details in areas such as packaging, security printing, and medical imaging. New laser scanning technologies have increased dot placement accuracy, improving print quality.

Next-Generation Toner Formulations

Pulverized toner has now been replaced by polymerized toner. Advanced toner technology requires lower fusing temperatures, which reduces power consumption.

Advanced Fusing Technologies

Nowadays, induction and LED-based fusing systems have replaced traditional heated rollers in electrophotographic printing. These new technologies allow machines to be ready faster and consume less energy, saving both time and electricity. In addition, xerographic fusing technologies such as belt-based and hybrid heat-pressure systems have ensured better image stability and durability on a variety of papers and materials. These technologies have now made prints clearer, more durable, and longer-lasting.

Electrophotographic Printing for Variable Data and High-Speed Production

Variable data printing (VDP) capabilities are enhanced by the integration of AI-driven print optimization and real-time data processing. This is beneficial for transactional documents, personalized marketing, and security printing, where high-quality output with personalized content at high speed is required.

Applications of Electrophotographic Printing Technology.

Applications of Electrophotographic Printing Technology

Electro-photographic printing, a form of digital imaging, has become the backbone in various sectors due to its fast operation, exceptional accuracy, and cost-efficiency.

Commercial Printing and Publishing

Electrophotographic (EP) printing has taken a massive turn in the publishing industry from a small print job to a large-scale one that has forever changed the relationship between companies and their vendors. Companies can now print brochures, catalogs, magazines, and books on demand without carrying large amounts of inventory. EP machines enable faster setup and faster turnaround than traditional offset printing; therefore, they are well-suited for customized and time-sensitive print jobs. Particularly valuable for marketing agencies and small publishers that need professional results quickly.

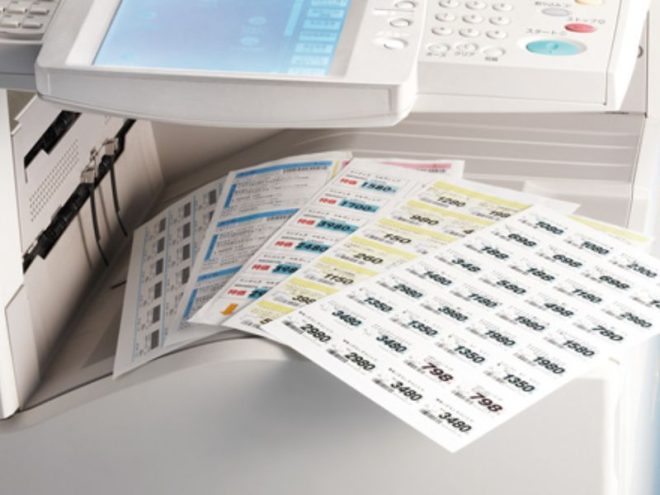

Packaging and Labels

EP technology has opened up vast new horizons for the packaging industry. As a rising trend in consumer demand for personalized packaging emerges, EP printing fills the gap, particularly within e-commerce and premium products. EP printing enables companies to print small runs of custom labels, folding cartons, and flexible packaging with vibrant colors and detailed graphics. Eye-catching packaging can thus be realized without large-scale print jobs; the opportunity is particularly beneficial for seasonal, promotional, and niche-market products.

Security and Transactional Printing

Another important area for security printing is where EP technology excels. Whether it is currency notes, ID cards, legal paperwork, or bank documents, the high resolution and accuracy of EP printers will ensure that all security features, invisible ink, and tamper-evident elements are accurately reproduced. Special toner formulations like UV-sensitive and duplication difficult.

Industrial and Textile Printing

The industrial sector currently applies EP printing as a method of direct application on plastic, ceramic, or synthetic fabric surfaces. It further serves the purpose of adding brand identity to promotional gifts, decorative tiles, and clothes. Further development in how well toners stick has made it possible to print even on complex curved surfaces with excellent sharpness and durability; this opens up new avenues for both designers and manufacturers.

Future Trends in Electrophotographic Printing

Hybrid Printing Systems

The combination of electrophotographic and inkjet technologies represents a new direction in the world of printing. This integration not only improves print quality but also enables printing on a variety of surfaces. Its increased durability, vibrant color depth, and workload intensity make it an attractive option. This technological convergence has given companies the opportunity to expand beyond traditional printing to industrial-scale applications. This advanced printing method is redefining modern printing solutions by combining speed, precision, and creativity.

Sustainability and Eco-Friendly Printing:

Environmental protection has also been taken into consideration as the printing industry moves towards development. Low-energy fusing technologies are being used to reduce energy consumption in printing processes. Toner recycling programs are also being adopted. Bio-based toner formulations have also been developed, which use natural and environmentally friendly materials instead of chemicals. The adoption of closed-loop waste management systems has brought about a huge change in EP printing.

AI and Automation in Print Production

Machine learning algorithms are being adopted in the EP printing workflow to maintain color uniformity and identify printing errors. This makes production efficiency more efficient and reduces unnecessary material wastage. This will conserve resources and reduce pollution.

Expansion into 3D Printing and Functional Printing

Electrophotographic 3D printing is opening up new opportunities for modern industries. These technologies are being used in electronics manufacturing, biomedical devices, and robust structural parts. With its help, complex designs, micro textures, and smart surfaces are being created in a better way. This 3D printing is leading industries to become more efficient, powerful, and advanced.

Conclusion

Electrophotographic printing technology is on an increasingly significant growth path, providing agile solutions to modern industries. For businesses looking for quality, consistency, and innovation in their printing processes, electrostatic printing offers an attractive option for the future. Advanced fusing methods, improvements in toner composition, incorporation of new technologies, etc., all make it a strong pillar of digital printing.

Source: